Coilovers 101

January 22, 2018 1 Comment

What are coilovers?

Suspension is one of the most vital components of your vehicle. Whether you just want to go low or are looking for a performance upgrade, you should always inform yourself before buying. In this post, we will be explaining the different types, and functions of coilovers that Grassroots has tested.

We begin with the basics.

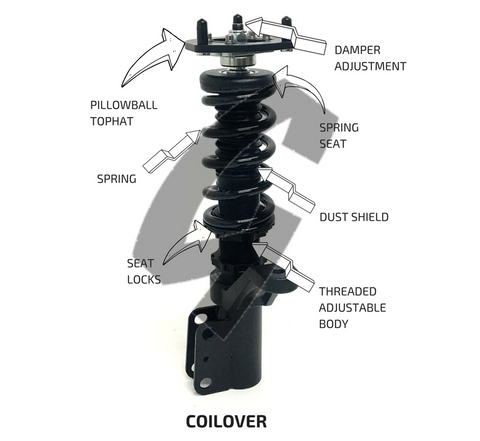

What makes a coilover? Take a look at this diagram.

Springs control the amount the suspension moves up and down, and struts/dampers, the other main component, controls how fast this movement happens. In a real-life driving situation, the spring would determine the amount of roll, squat, and dive of your vehicle. While the dampers would control the speed at which these actions happen. Ultimately, the combination of the 2 is what decides the ride quality and performance of each unit.

Spring Type Basics and Spring Rate Conversions

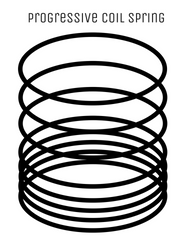

Progressive Springs are used on non-adjustable units. Example being, a standard OEM assembly or a mere simple lowering spring. This means there is no exact spring rate number. The spring is designed to fluctuate as the driving force and pressure are applied. This would be more for a generic setup where performance is not the key upgrade intent.

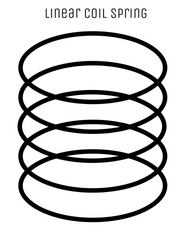

Linear Spring rates are set numbers. This means the weight needed to compress that spring under load does not change. This setup delivers much higher performance but comes with a stiffer ride. Linear type springs are found on the most common coilover setups.

Spring rates can get pretty technical when calculating. The stiffer the spring, the less travel the suspension will have. Weight and driving type must also be taken into consideration. Street, Drifting, Drag racing, Circuit, Rally, Autocross etc... all have different requirements. Most commonly seen is a spring rate given in KG/mm or LBS/in. This means the weighted force / the space traveled. For example, 700LB/in would mean 700 pounds will compress that spring 1”. This can also be read as 12.5K/mm (12.5kg to compress spring 25mm). Below is a simple chart of just a few spring rate conversions.

Spring Rate Conversion

Approx 1KG/mm = 56LBS/inch

700 lb/in = 12.5 kg/mm

650 lb/in = 11.6 kg/mm

600 lb/in = 10.7 kg/mm

550 lb/in = 9.8 kg/mm

500 lb/in = 8.9 kg/mm

450 lb/in = 8 kg/mm

400 lb/in = 7.1 kg/mm

350 lb/in = 6.2 kg/mm

300 lb/in = 5.3 kg/mm

250 lb/in = 4.5 kg/mm

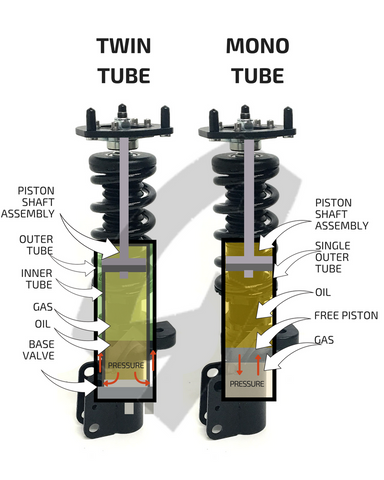

Twin-Tube vs Mono-Tube

Twin-Tube

This is a major fundamental when it comes to coilover units. Especially since both types can look physically identical to each other. Twin-Tube construction is made with an inner and outer tube. The smaller diameter inner tube, is where the piston shaft, valve, and oil are found. The larger outer tube houses damper oil, and nitrogen gas. Twin-tube construction is commonly found on most OEM units or street style coilovers. The reason for this is the ratio of piston stroke to body length. Meaning there is more piston movement internally of the unit. This gives a more comfortable ride, and has a high tolerance outer tube for longevity. A quality twin-tube construction usually has between 19-24 levels of dampening. This allows adjustable ride quality and performance. Although this design is not recommended for racing or track vehicles.

Mono-Tube

Mono-Tube setups come standard equipment in some high-performance factory vehicles, and often the design used in higher quality aftermarket racing suspension. Mono-Tube design has one outer tube. The oil and gas chambers are separated by a floating valve style piston. This setup puts the damper oil on top and damper gases on the bottom. The simple design allows this unit to have larger, stronger internal parts. This combination equates to more oil/gas capacity, more damping force, and much better heat dissipation under continuous load. Under race driving conditions, the internal valve moves more toward the gas chamber, which gives the unit quicker, more aggressive response outputting higher performance capabilities. Some mono-tube setups can also be designed inverted, which mounts the damper upside-down on installation.

Launching early 2018, all Grassroots Performance coilovers sets will be made using mono-tube construction. The dampers are valved specifically to our specifications, and the spring rates are decided on by use of the vehicle.

1 Response

Leave a comment

Comments will be approved before showing up.

Also in Technical

Sign up to get the latest on sales, new releases and more…

![Track Test of our Grassroots Performance 19-Row Oil Cooler [PROVEN]](http://grassrootsparts.com/cdn/shop/articles/Track_Test_of_our_19-Row_Oil_Cooler_1600x.jpg?v=1696426120)

Marc

May 22, 2018

Wicked, thanks to your team for the info